Hi i don't know what to do with my switch as i told u guys before its on 2.2.0

Should i give up on hopes of having cfw and roms and should i update to the latest 5.1.0 and play fortnite cuz its a free game

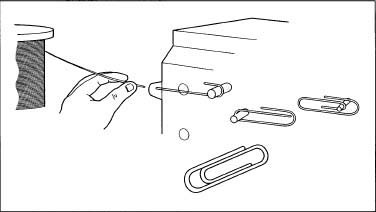

I can't order tx sx nor can i make a paperclip mod

Will there really be a browser exploit for fws 3.0.0 and below and will atmosphere be supported

If they manage to create a emunand won't it still burn efuses right?

So should i just update to 5.1.0 and buy games from eshop/physically

Should i give up on hopes of having cfw and roms and should i update to the latest 5.1.0 and play fortnite cuz its a free game

I can't order tx sx nor can i make a paperclip mod

Will there really be a browser exploit for fws 3.0.0 and below and will atmosphere be supported

If they manage to create a emunand won't it still burn efuses right?

So should i just update to 5.1.0 and buy games from eshop/physically